GateStone

GateStone

GATE Precast Company’s foundation is built on the prefabrication of GateStone, one of the most versatile exterior systems on the market today. Born from efforts in the early 1900s, the materials used today give designers the freedom to express their design ideas in a variety of ways.

Architects are taking advantage of concrete’s structural nature in self-supporting applications, innovative mix designs and GateLite, a lean architectural concrete skin.

Aesthetic Versatility

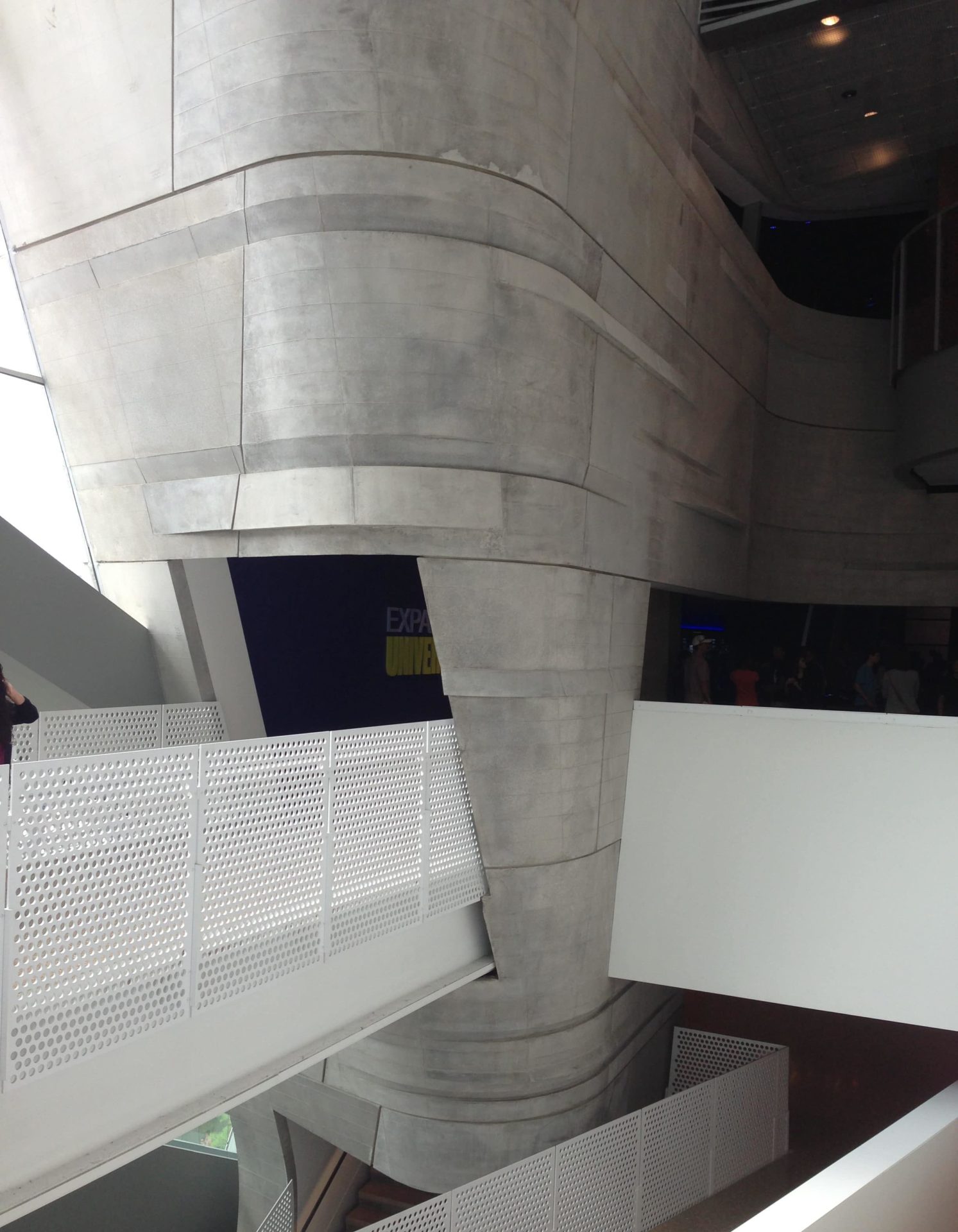

Nonlinear designs utilizing modules

Aesthetic Versatility | Parametric Shapes

Designing with Architectural Precast Concrete is an open canvas providing a façade material that leverages the full power of parametric modeling programs leading to iconic buildings. Pairing models with generative design tools allows designers to pursue these complex shapes while keeping workflow efficient.

Aesthetic Versatility: Multiple finishes in single panels

Aesthetic Versatility: The full size precast mockup incorporates a significant level of three dimensionality with heavy vertical projections for Navy League headquarters in Arlington, VA. Three mix designs were used with two finishes – white precast with a light acid wash finish at the lower levels and two buff-colored mixes with medium acid washes above.

View Unlimited Color Options

Facade Integration: Precast concrete integrates easily with other systems and any architectural feature can be integrated into a precast system — brick, natural stones, tile, pediments, wainscot, heads, sills, conduit and insulation.

Historic Compatibility

The ability to leverage architectural precast’s design flexibility allows designers to meet the criteria of many of the nation’s Board of Architectural Review who ensure the preservation of historical districts.

The Bryant is the first-ever residential condominium built on Bryant Park in NY and the first ground-up residential tower in the U.S. designed by Chipperfield Architects. GATE Precast worked directly with Chipperfield and HFZ Capital Group in a design-assist partnership for seven months during the development of the unique tower, which had to adhere to the conditions of the historic neighborhood’s Landmarks Preservation Commission. To see how GATE Precast successfully achieved the commission’s approval on a unique terrazzo GateStone polished finish, View Project.

Adaptive reuse: Architectural precast can be used to reclad existing structures for adaptive reuse using self-supporting options, as well as using GateLite, a wall panel system comprised of a 2-¼” architectural precast concrete skin fixed to a structural steel tube frame.

Above, the two 1960s-era Longwood University residence halls in Farmville, VA. stand prior to being rebuilt from their existing steel frame with an insulated architectural precast concrete walls system. Replacing the concrete masonry units gave Little Diversified the opportunity to create a new image that provides a transition to welcome the town to campus.

Johns Hall and Moss Hall at Longwood University were excellent candidates for renovation and adaptive re-use. The new self-supporting insulated architectural precast façade will retain the look of the basic buildings alumni remember. Renovating the dorms rather than demolishing to build new structures will save tens of millions of dollars as well as months of construction.

Efficient Design: Our team engages stakeholders early in a project’s design to find creative and efficient solutions that minimize cost, streamline schedules and yield quality precast concrete systems tailored for the client’s specific needs.

The panelization scheme for the Louisville Omni Hotel combines three panels into one “M-Shaped” panel. The accent above every other floor provides a consistent and intriguing pattern. The larger panel sizes minimizes the number of joints and accelerates the installation. This visually dramatic hotel has changed the downtown skyline of this river city.

The panelization scheme for large punch window units offered an efficient solution for Opus Hall, CUA, Washington, DC. The pre-insulated architectural precast wall panels are 12’-4” tall x 30’ long with 3’ returns and are embedded with over 2,200 bricks. The panels are self-loading with lateral tiebacks for wind loads and erected in less than 20 minutes.

Production Efficiency

LEAN manufacturing is implemented at all of GATE’s state-of-the-art manufacturing facilities, which yields monumental outcomes such as higher quality level and more efficient turnaround. GATE’s “Lean Thinking” positively impacts ownership through removal of potential wasted material and person-hours; hence providing a more cost-effective product.

The ability to manufacture architectural precast components in an environmentally controlled fabrication setting and install in virtually all weather conditions increases speed at the site and plant labor efficiency.

Site Efficiency | Accelerated construction: This time-lapse video, shows the erection process of precast components for the St. Vincent DePaul Elementary School, Long Beach, MS., which was rebuilt after Hurricane Katrina. While the site was cleared and foundations laid, GATE Precast fabricated pre-insulated architectural precast panels embedded with thin brick off-site. A small crew can erect thousands of square feet per day and enclose a structure in days or weeks.

Thermal Efficient: Architectural precast systems meet today’s challenging ASHRAE and green building requirements with the ability to track air, vapor and thermal lines around the exterior envelope.

The University of Kentucky’s Albert B. Chandler Hospital Pavilion had to have a high performance envelope that would improve energy efficiency, while harmonizing with the campus and shaving a year off the construction schedule. The architectural precast system combined a continuous air and vapor barrier, as well as continuous insulation, efficiently into one system. This provided an effective R-value of 27 and saved time, material and money. Precast also provided the aesthetic versatility to offer several finishes in one system.

The Design Assist Delivery method has several advantages to a Traditional Delivery Method:

- Time savings gained when precast shop drawings are developed during the design stage leading up to construction documents.

- Reduction of potential post bid redesigns due to budget issues or items discovered during the bid process.

- Costs can be tracked on a weekly or bi-weekly basis giving the owner real-time information direct from the sub-contractor about design changes or issues as well as how they relate to the other trades. Over time, this allows the owner to enhance probability by reducing contingency and moving this capitol into other assets or to overall cost savings.

Risk Reduction | Reduced Trades:

Pre-installed windows conservatively saved 8 months on the schedule of One South First, Brooklyn, NY, and allowed the interiors program to start earlier than the traditional delivery methods of windows.

Structure Durability | Long Service Life

With its impenetrable surface, architectural precast concrete facades offer an exterior that requires little maintenance over its service life, reduces life cycle costs while preserving the original aesthetic features.

The Church of Latter-Day Saints Temple in Orlando, FL features a pure white architectural precast facade. The temple opened in 1994 and stands today as a testament to the resiliency of architectural precast concrete. With its marble enhanced mix design and acid-etch finish, the facade reacts with the sun as if it was installed yesterday. >

Multi-Hazard Protection | Storm Resistance

The Inherent capabilities of architectural precast concrete give it the capacity to withstand extreme weather conditions such as category 5 hurricanes and EF5 tornadoes. With design assistance, these structures can efficiently meet FEMA 361.

Precast Concrete FEMA Shelters Keep Communities Safe, Ascent Summer 2019

Online Exclusive – Thoughts from a Tornado Veteran, Ascent Summer 2019,

Resilience is the New Sustainability, Ascent Summer 2019

Gulfport’s U.S. Courthouse, designed to meet federal requirements for blast loading and other stringent zoning codes, withstood Hurricane Katrina’s impact better than surrounding buildings. The courthouse was subjected to 132-mph winds during the height of the hurricane. The only apparent damage to the building was a few broken windows, a small area of broken granite and a few missing letters above the main entryway.

The eight-story, 180,000-gsf Dan M. Russell, Jr. U.S. Courthouse features an architectural precast exterior with granite cladding around the base and entry and towers over the community affording spectacular panoramic views of the Gulf of Mexico and the Mississippi Sound.

Multi-Hazard Protection | High Seismic Activities

GATELite, an innovative lightweight panel, performs well in seismic areas reducing structure and connection costs, while maintaining the traditional attributes durability, long service life and multiple finishes.

The primary design challenge for the Ransom Everglades STEM building in Miami, FL, designed by Perkins + Will was to provide a facade system that imposes no more than 48psf dead load, serve as a rain barrier, convey the three-dimensional architectural surface articulation and withstand the rigorous hurricane wings South Florida has to offer. >

Multi-Hazard Protection | Blast Resistant

Operational Readiness Training Complex (ORTC)

Camp Shelby, MS

The four, four-story total precast barracks feature insulated load-bearing exterior walls, and double tees. The main design challenge was to incorporate precast panels into a facility required to meet progressive collapse, which conformed to UFC 4-023-03. The project was built to be a 100-year plus facility and being constructed with an all precast system extends the life cycle of the facility and withstands even the most extreme Gulf Coast weather conditions. The barracks were built to be used for housing during hurricane events.

Life Safety and Health | Indoor Environmental Quality

Architectural precast wall panels were used on both the exterior and interior of the Florida Hospital in Winter Garden, FL, which inherently help provide a healthy environment for its occupants and the basket weave patterning creates visual interest.

Crescent Central Station, Orlando, FL – an all precast parking structure surrounded by multiple stories of apartments.

Life Safety and Health | Passive Fire Resistance

In the interest of life safety and property protection, building codes require resistance to fire be considered in the design of buildings. Precast concrete is inherently noncombustible (passive fire resistance) and can be designed to meet any degree of fire resistance that may be required by these codes. Non-combustible concrete construction delivers lower insurance rates to owners due to the higher fire-resistant designs that incorporate containment and repairs to structure post-event.

Factors determining the durations to meet the ASTM E119 tests range from thicknesses, sands, and aggregate selection but range from two to four hours with thicknesses of 4” to 7”.